- December 7th, 2022, 11:47 am#4974951

Hello GBFans it’s been a few years. Sorry to have ghosted you but lots have happened since my noobie days on the forum.

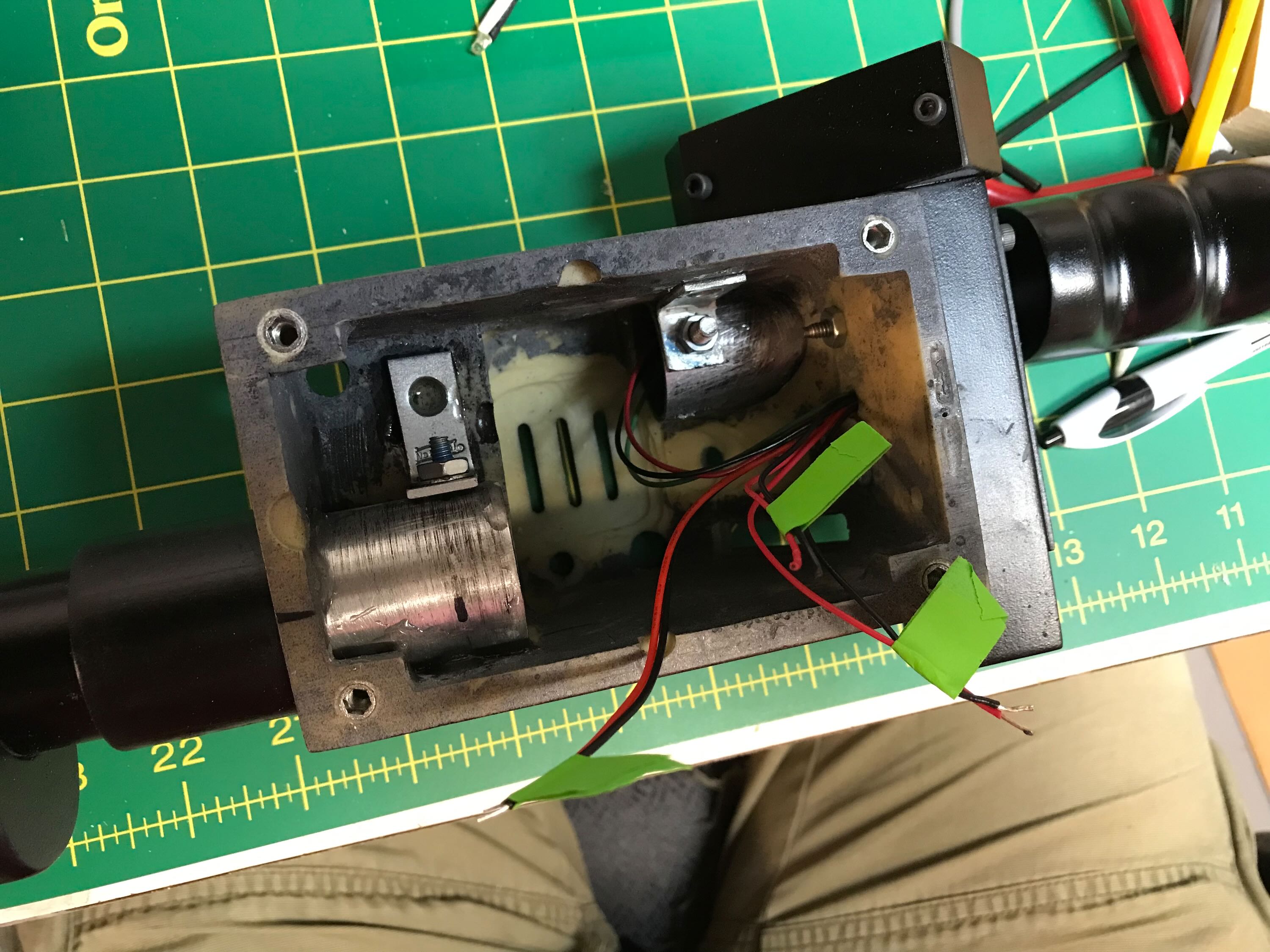

Anyway, I’m starting a second full pack build, Benofkent, for someone the next state over from me. No idea what generation pack it is but my question isn’t so much how to build it.

I want to know, as I’ve been away for a while, how much harder it is to find genuine or accurate looking parts for full-pack, non-Spirit, builds.

To give an example: small brass washers for thrower front handle and individual aluminum makers outside of GBFans.

I’m one of those accuracy builders who tries to avoid 3D printed parts for externals as they are not my cup of tea.

who tries to avoid 3D printed parts for externals as they are not my cup of tea.

Anyway, I’m starting a second full pack build, Benofkent, for someone the next state over from me. No idea what generation pack it is but my question isn’t so much how to build it.

I want to know, as I’ve been away for a while, how much harder it is to find genuine or accurate looking parts for full-pack, non-Spirit, builds.

To give an example: small brass washers for thrower front handle and individual aluminum makers outside of GBFans.

I’m one of those accuracy builders

2014-2015 "Betty" - My Pack Build: http://www.gbfans.com/forum/viewtopic.php?t=38499

2015 - Thrower Build: http://www.gbfans.com/forum/viewtopic.php?f=2&t=39129

2016 - "Betty" Upgrades : http://www.gbfans.com/forum/viewtopic.php?f=2&t=40443

CPS Prop Builds (Instagram): CPSPROPBUILDS

Member of MAGB: http://www.facebook.com/MAGhostbusters

2015 - Thrower Build: http://www.gbfans.com/forum/viewtopic.php?f=2&t=39129

2016 - "Betty" Upgrades : http://www.gbfans.com/forum/viewtopic.php?f=2&t=40443

CPS Prop Builds (Instagram): CPSPROPBUILDS

Member of MAGB: http://www.facebook.com/MAGhostbusters

[/url]

[/url]

- By pda4ever

- By pda4ever